Tungsten Copper Heat Seat

Tungsten copper heat seat is used extensively in thermal mounting plates, chip carriers, flanges, and frames for high-powered electronic devices. As a copper tungsten composite, it utilizes the thermal advantages of copper and the very low expansion characteristics of tungsten.

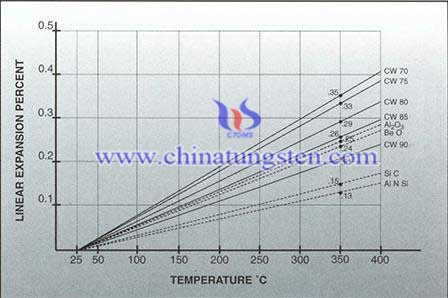

The combination of these two materials results in thermal expansion characteristics similar to those of silicone carbide, aluminum oxide, and beryllium oxide, used as chips and substrates. Because of CuW's thermal conductivity and expansion characteristics, it works well in densely packed circuits.

Features of CuW include:

Minimizes thermal stress

Can be mounted to directly

Can be plated with silver, gold, nickel, and copper

Readily brazable without distortion or loss of physical properties

Non-magnetic

Maintains high physical properties over a wide range of temperatures

Remains stable during temperature cycling

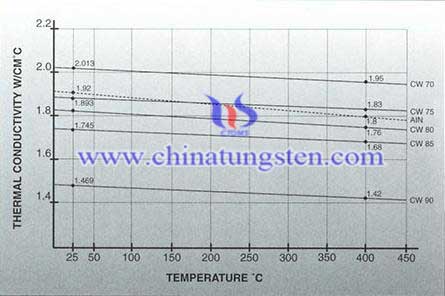

High electrical conductivity, varying with the grade

Superior thermal conductivity

Various grades are available to match the characteristics and requirements of the material attached to it

Can be readily machined into complicated shapes

Parts can often be made to net or near net shape, because they are manufactured by powder metallurgy

Thermal Expansion

Thermal Conductivity

Related dates:

| Type | Composition | Properties | ||||

| element | Content wt% | Density | CTE ppm/K | TC, W/m·K |

||

| Mass density, g/cm3 | Relative density, %T.D | |||||

| W90Cu | W Cu |

90±1 balance |

17.0 | ≥99 | 5.6~6.5 | 180~190 |

| W85Cu | W Cu |

85±1 balance |

16.3 | ≥99 | 6.3~7.0 | 190~200 |

| W80Cu | W Cu |

80±1 balance |

15.4 | ≥99 | 7.6~9.1 | 200~220 |