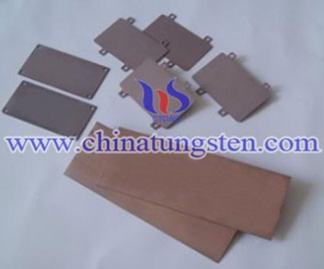

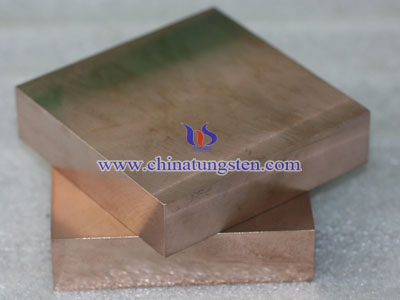

Tungsten Copper Heat Seat

Tungsten copper heat seat material is a composite of tungsten and copper. Tungsten Copper Alloy is the metal mostly used in heat sinks, which draw heat away from the more heat-sensitive elements inside electric devices. W-Cu material with both tungsten low expansion characteristics, but also has copper of high thermal conductivity properties, and the tungsten and copper in the thermal expansion coefficient and thermal conductivity can adjust the W-Cu composition and to design (with professional terms, tungsten and copper in the performance can be cut), and thus the application to the tungsten and copper brought great convenience. The produced tungsten copper alloy is with the good thermal expansion match with the following material:

Ceramic materials: Al2O3 (A-90, A-95, A-99), BeO (B-95, B-99), AlN, etc.;

Semiconductor materials: Si, GaAs, SiGe, SiC, InGaP, InGaAs, InAlGaAs, AlGaInP, AlGaAs, and so on.

Metal Material: Kovar alloy (4J29), 42 alloy;

Tungsten Copper Features:

The product does not add Fe, Co and other elements of the sintering activation, to maintain a high thermal conductivity.

The product can provide semi-finished tungsten or copper-plated Ni / Au finished.

The product has excellent copper tungsten tightness.

The tungsten and copper products have good size control, surface finish and flatness.

The product provides pre-W-Cu sales sale the whole process of technical services